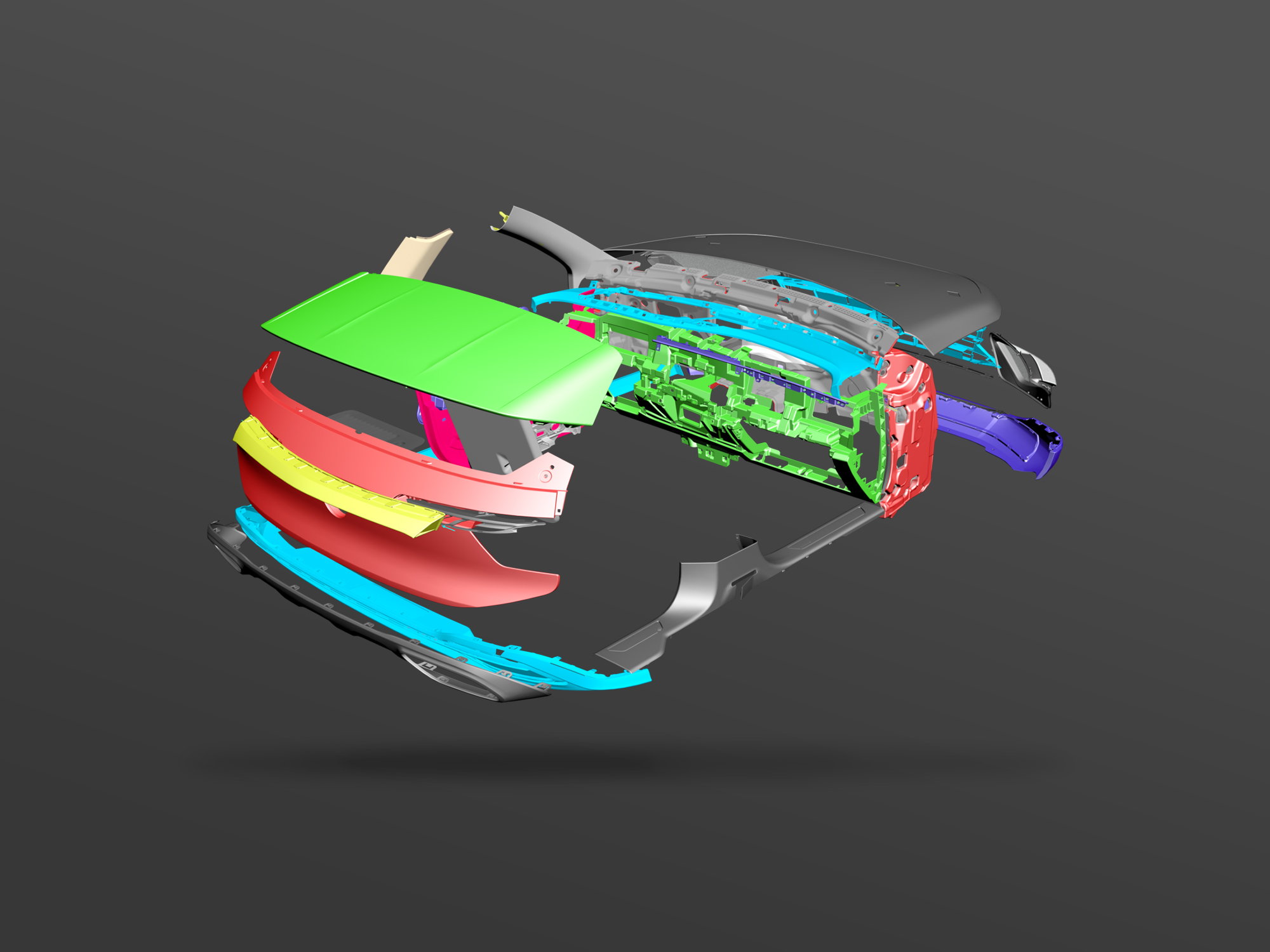

components

components

TOOLMAKING & DEVELOPMENT

WE ARE MÜLLER WALLAU

An innovative product range in the field of toolmaking is the central element of our sustainable corporate development. As a leading technology company, we accompany our customers from the initial idea through to series production.

Our customers rely on our expertise

CURRENT

JOB & TRAINING

#Tool mechanic #Technical product designer #Cutting machine operator #Eroding machine operator #Process mechanic #Plastics technology

-> VISIT OUR JOB ADVERTISEMENTS ON KARRIERE MITTELHESSEN!

We are always happy to receive unsolicited applications!

Still looking for an apprenticeship? Apply now for the 2026 training year.

WHAT WE DO

TOOLMAKING & PLASTICS TECHNOLOGY

We combine innovative product ideas with sustainable moldmaking technologies. To this end, we rely on development and in-house production. None of our tools are the same. This is what gives our company its character.

SOLUTIONS FOR PREMIUM PRODUCTS

Premium products means individuality. Our virtually unlimited range of technologies for products between 2g and 8000g offers our customers maximum flexibility in their production.

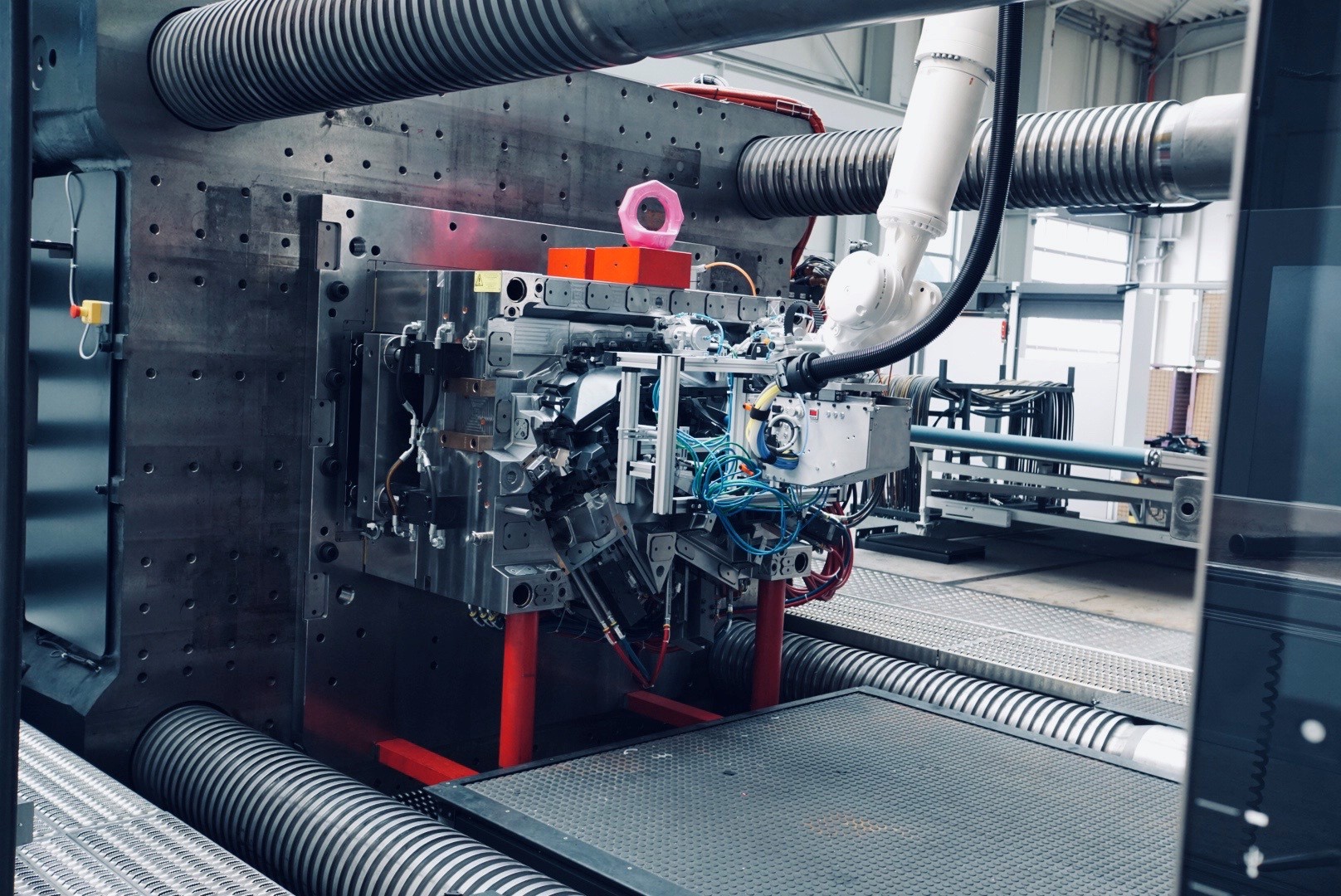

QUALITY

IS A PROCESS

We use three injection moulding machines to produce near-series samples or near-series development components with a clamping force of up to 3000t. Our technical center offers an ideal development environment for processes and materials.

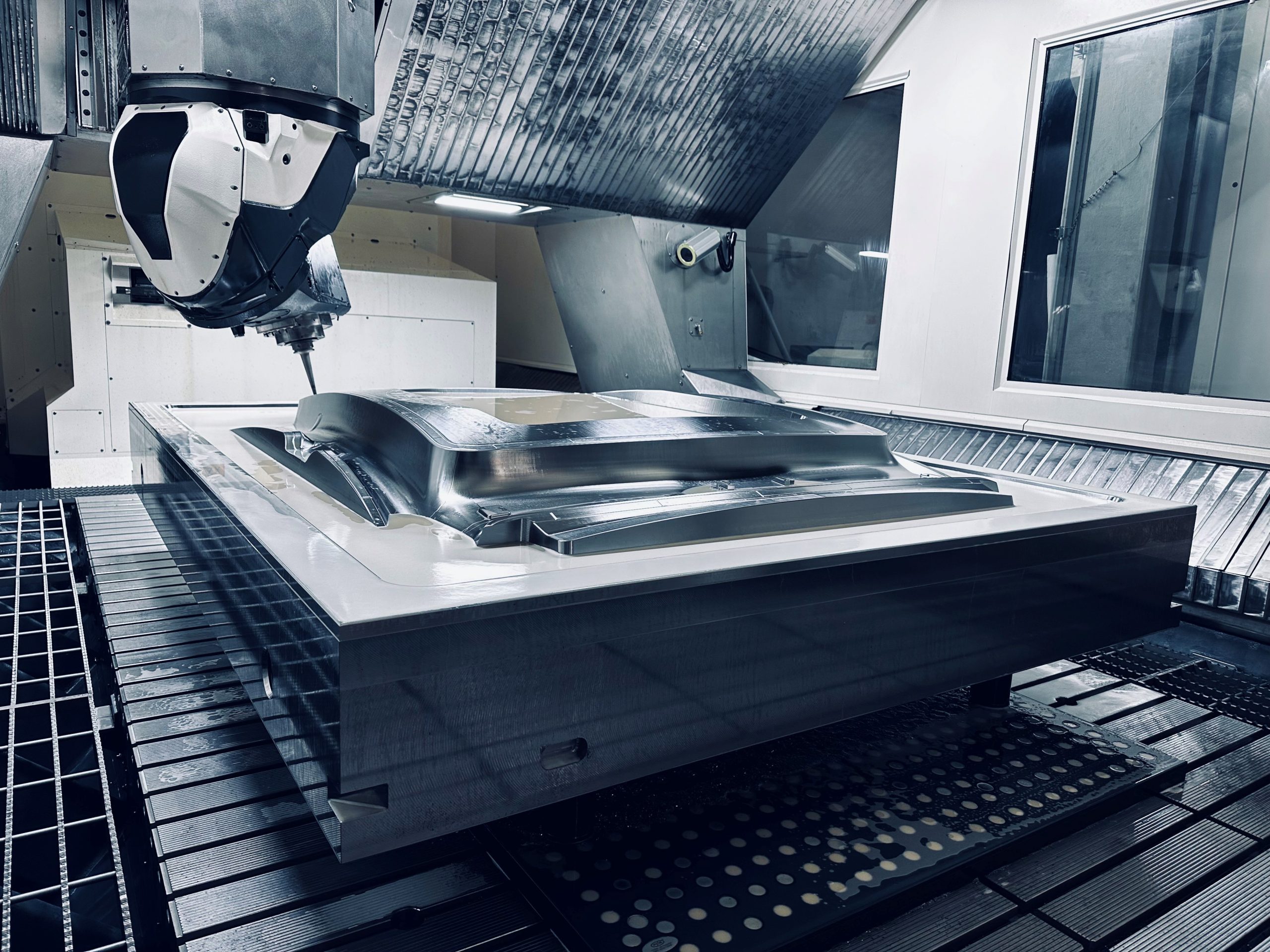

TOOLS

KNOW HOW & TECHNOLOGY

For us, shaping the moldmaking of tomorrow means bundling all competencies. In our tool shop, more than 120 employees work on the implementation of the latest technologies. With over 50 processing machines, we specialize in large-scale projects and efficient development components.

Employees

Year established

Tons

Tools / year

NEWS

Training fair

On 13.03 and 14.03 we will again be taking part in the training fair in Biedenkopf.

DMF 300 linear

We are expanding our machine park with a linear-driven HSC milling machine from DMG

Employees anniversary

We celebrate the company anniversary of 16 employees with a potato roast.

DMU 400G

With our new DMU 400G, we have increased our milling capacity for components up to 4400x2200.

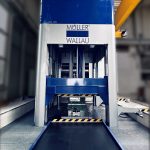

Spotting press

We are expanding our spotting capacities with a new spotting press for large tools.

Training fair

We will participate in the training fair from 10.03 - 11.03.2023 in Biedenkopf.

Employees anniversary

We celebrate our employee anniversary in 2022.

3000t SGM

Our new Engel 3000 was put into operation.

Hermle C400

We are expanding our 5-axis small parts production with a Hermle C400 with pallet automation.